Your journey to energy efficiency starts here

EECA’s wood processing and manufacturing energy toolbox provides free tailored tools and resources for businesses to help the sector save money and be more energy efficient.

Clean and clever energy project at Whakatane Mill

2 minutes 18 seconds

Whakatane Mill has made a commitment to ongoing sustainability, investing in leading clean and clever technology to secure the future for its workers and the wider community.

The opportunities for wood processors and manufacturers

- Wood processing and manufacturing systems use a significant amount of energy to produce hot water, steam or drying to make wood-based products. This is typically generated on-site using furnaces, boilers or thermal oil heaters.

- The sector covers wood product manufacturing like sawmilling, timber dressing, panels, engineered wood products, and forest bio products. It also covers pulp and paper production.

- The biggest opportunities for energy saving are using heat recovery systems, boiler controls, and variable speed drives on electric motor systems such as dust fan extractors. The industry also has an opportunity to explore full utilisation of forestry residues for energy generation on site along with looking at use of demand flexibility to take advantage of lower price electricity rates.

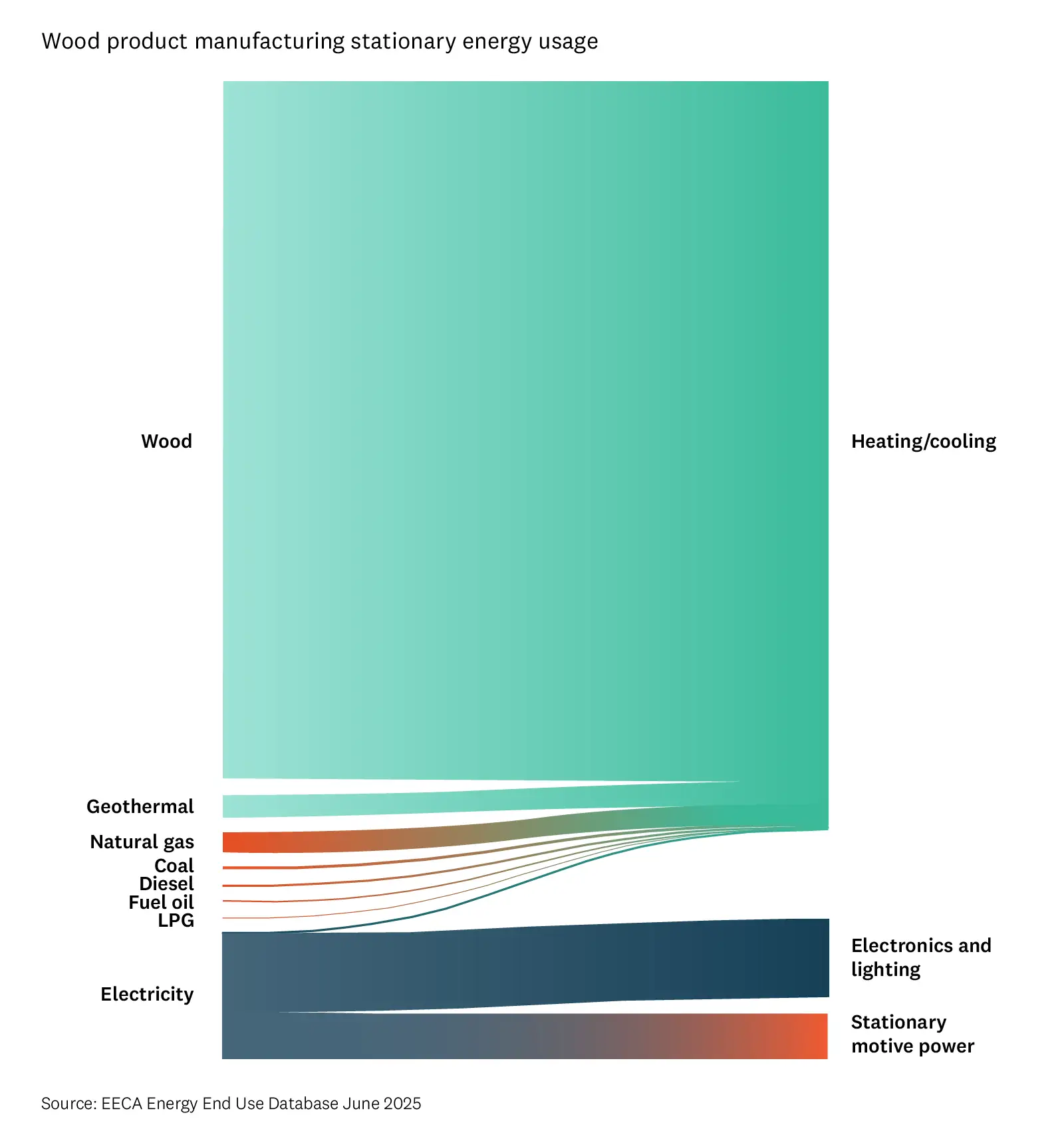

- Currently the industry uses its residual wood biomass to generate energy, which along with electricity, is the main source of energy, followed by use of gas, geothermal energy and other fuels. Biomass through log residues, such as bark, chips and sawdust, form the major percentage of energy production within the industry, with some mills energy inputs made up entirely of the renewable biomass energy source.

- This energy toolbox focuses on managing fuel use and electricity loads for the wood processing and manufacturing sector, improving energy efficiency and helping to reduce costs.

Tools and resources

These dedicated tools and resources have been designed by industry experts especially for the wood processing and manufacturing sector.

This energy toolbox will identify, measure, optimise and reduce fuel and energy demand in your business.

Work your way through them at your own pace, put the lessons into practice, and start seeing results.

3 steps to reduce your carbon footprint

The Wood Processing and Manufacturing Sector energy toolbox starts with energy efficiency. The end goal is to reduce carbon emissions and manage energy loads, but by first taking steps to improve existing processes, equipment and operations, you will be more efficient and more cost effective.

Step 1: Measure emissions and set targets

The most important step in energy management and conservation is measuring and accounting for energy consumption.

Step 2: Optimise equipment and improve processes

Reviewing and adjusting the way your equipment is performing can be a big win for energy reduction, cost reduction, and increased productivity.

Step 3: Demand and emission reduction opportunities

New technology or upgrades to existing processes can reduce energy demand. This step looks at equipping businesses with the latest innovations in their space to reduce the demand for energy.

Case studies and insights

-

Electric off-road machines

Businesses around the country are adopting electric off-road machines – and operators are impressed.

- Electric vehicles

- Decarbonisation

- Case study

-

Biomass boilers for industrial process heat

Information for businesses looking for low-carbon alternatives to fossil-fuelled boilers.

- Process heat

- Decarbonisation

- Fuel switching

-

Greener greens with less waste

Marlborough-based herb and salad green growers, Thymebank, have switched from coal to wood waste and nut shells for their glasshouse heating.

- Innovation

- Decarbonisation

Wayfinder

-

Stay up to date as we release new resources

-

Find other support opportunities

-

Browse sector pathways