Electric motors power tiny devices, like automatic door locks, through to large industrial systems. Within our homes and offices, electric motors are in most appliances, like refrigerators, computers, ovens and heat pumps. In our industrial sector, motors drive activities like mixing, crushing, drying and moving goods.

New electric motor technologies

The performance and energy efficiency of electric motors is improving rapidly because of advances in material science, design, electronics and other fields.

Switching to more efficient and sustainable electric motor technologies can have a significant impact on lowering energy bills, increasing productivity and achieving emissions targets.

To support the transition to new electric motor systems, EECA commissioned the Institute of Geological and Nuclear Sciences Limited (GNS Science) to carry out a technology scan of new and emerging electric motor technologies.

Electric motors use a lot of energy and collectively make up around 40% of New Zealand electricity consumption.

EECA Energy End Use Database 2022

Scope

The report describes new electric motor technologies and what conditions or applications they might be best used for. It covers:

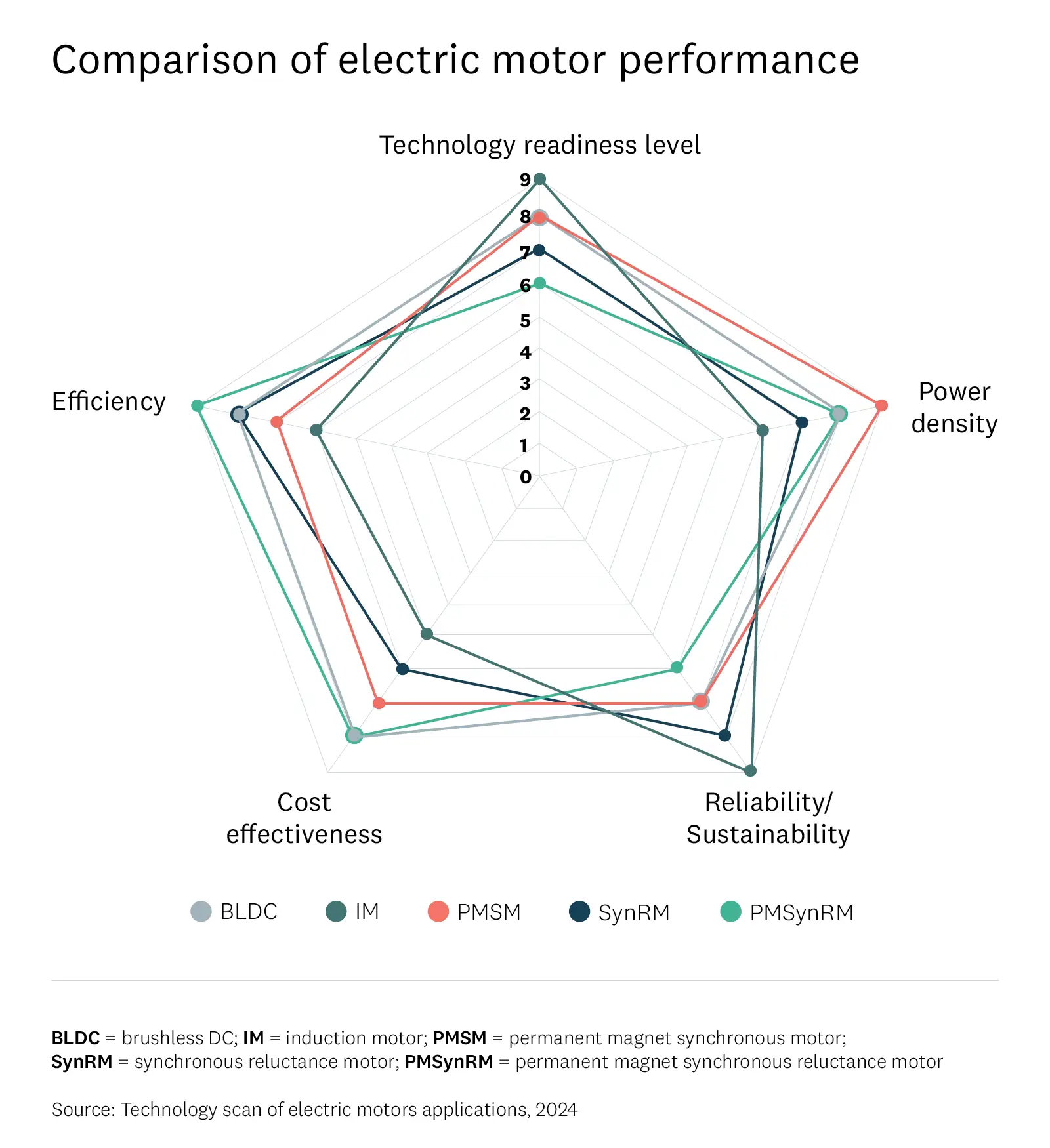

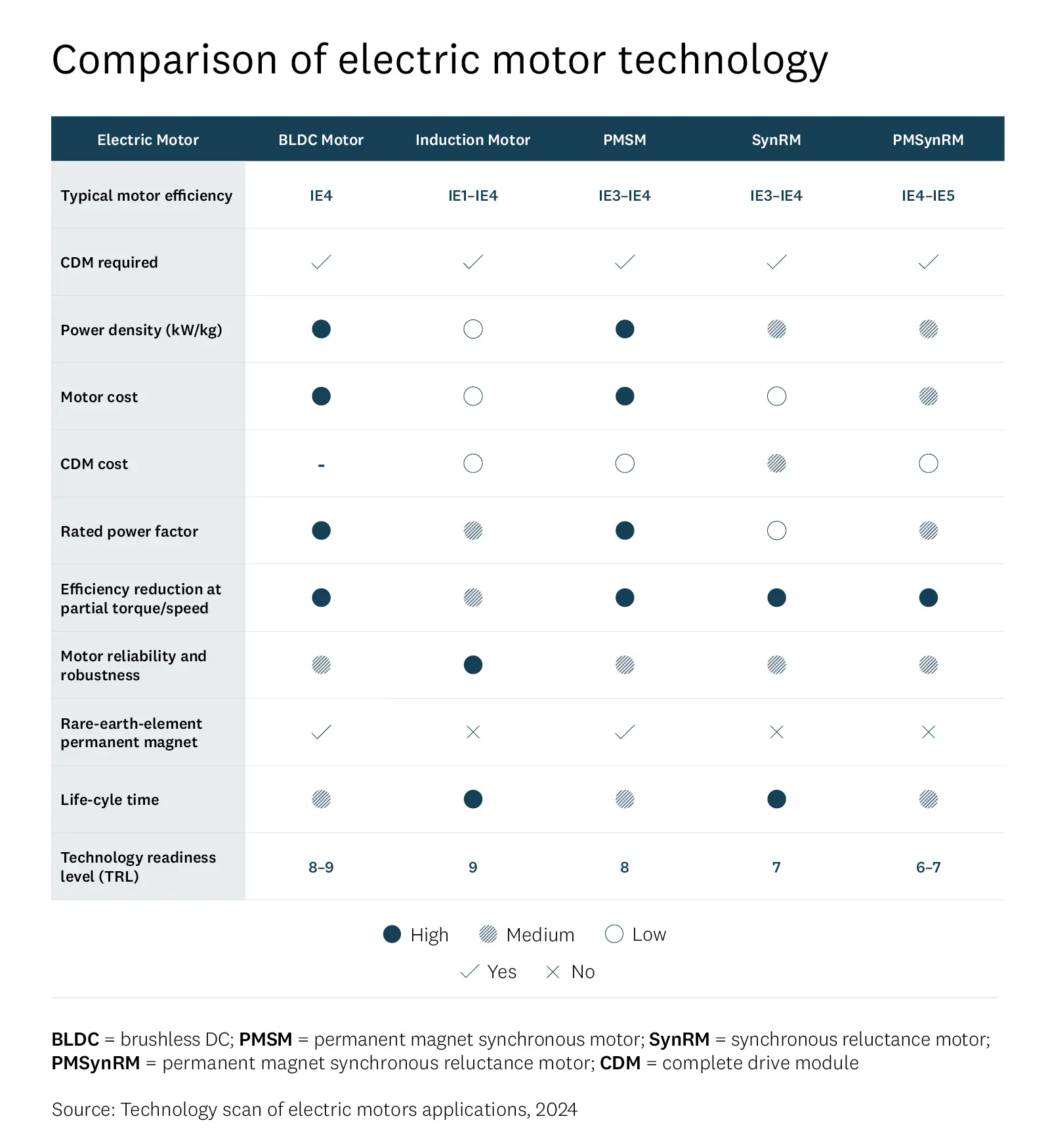

- the pros and cons of new types of motors – brushless direct current, synchronous reluctance, permanent magnet synchronous, switched reluctance and others

- motor flux designs – axial, transverse and radial

- new magnetic materials – amorphous alloys, crystalline alloys, iron-based and rare-earth based magnets

- current and emerging semiconductors for variable speed drives including the full range of wide bandgap semiconductor materials

- semiconductor switch geometries and design

- software optimisation using microcontrollers.

Intended audience

The technology scan is geared towards people looking to make decisions about their current motor systems or those thinking about how motor systems will change in the future. This might include:

- factory owners or operators

- production or engineering managers

- motor suppliers

- energy consultants

- product designers.

Key insights

New motor technologies offer higher performance and efficiency than existing induction motors.

Owners, designers and specifiers of motors systems should be aware of these new motor technologies and the reduced whole-of-life costs they offer.

There are pros and cons of different motor types.

To boost electric motor efficiency, motor manufacturers can reduce two types of energy loss.

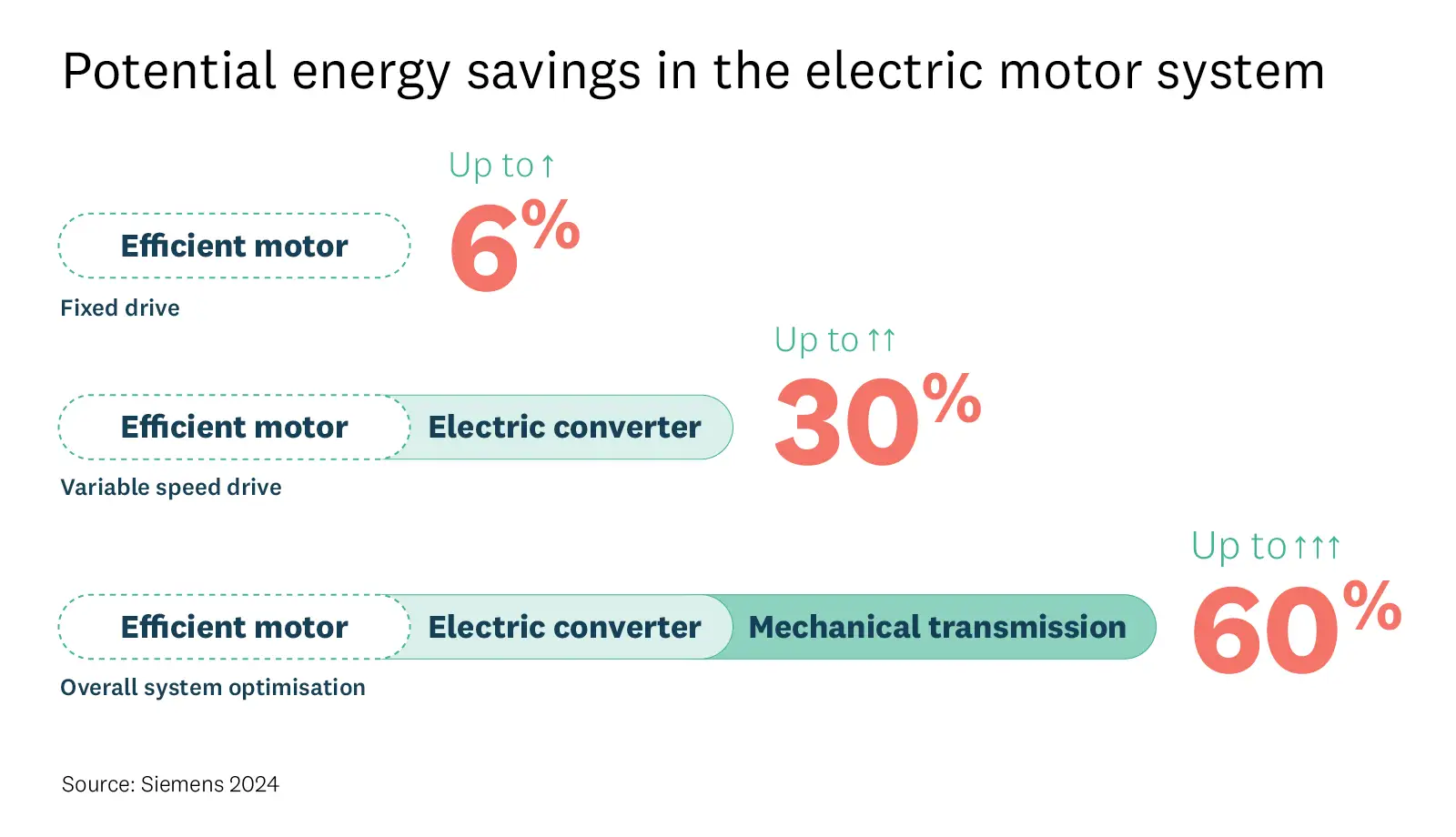

Drive systems are an important consideration and can deliver serious cost and energy savings.

For example, variable speed drives can potentially offer very large energy savings in systems with non-constant load. By reducing the motor speed to accurately match the load needed, the power demand is reduced. High efficiency drives using next generation semi-conductors offer even more energy savings.

Efficient motor system design incorporates all the components of the motor system.

For example, adding a more efficient motor into an inefficient motor-driven system would be less effective than optimising the whole system. It is for this reason motor-driven systems should be looked at holistically. Each of the components should be examined critically, and appropriately sized and specified.

Read next

-

Hot water heat pumps in commercial buildings

Information for businesses looking for a low-emissions solution to meet hot water and space heating requirements.

- Co-funding

- Decarbonisation

- Hot water

-

Food Product Manufacturing Energy Insights

Quantifying energy use for food product manufacturing in New Zealand.

- Process heat

- Decarbonisation

-

Energy Efficiency First

Overview and technical report on EECA modelling that shows nationwide uptake of energy efficient technology could significantly reduce the cost of meeting New Zealand’s ambitious renewable electricity goals.

- Electricity

- Decarbonisation