Process heat is primarily used for industrial processes, including in the form of hot gas, hot water and steam. In most instances, process heat is generated by burning fossil fuels such as gas or coal.

By considering a switch to renewable energy sources, industrial businesses can address rising energy costs and increase energy security.

On this webpage you can learn about the clean process heat technologies, their pros and cons, cost factors, and other considerations when choosing and implementing a fuel-switching solution.

Renewable energy options for process heat

- Wood-fuelled (biomass) boilers

- Heat pumps

- Electric boilers

- Biogas boilers

- A hybrid solution

Choosing the best solution for your business

The right process heat solution will depend on the specific needs of your business. If the options are carefully considered and explored, a renewable energy option should be available as a viable alternative to a fossil fuelled heat plant to generate process heat, and in many instances will generate an improved result.

Replacing your heating system is a good opportunity to improve operating costs, flexibility and efficiency while also ensuring suitable resilience and security for your operations.

The range of options is wide, but may include single heat plant, dual or multiple heat plant, single or dual fuel, energy storage (thermal, electrical, fuel), process interruption, process resilience (e.g. interim material hoppers), onsite generation and even fossil fuel backups.

Some things to consider include:

- Demand profile — One of the key determinants of suitable options is the demand profile, including daily variability, seasonal variation, and operation criticality. A steady demand profile is likely to suit a high temperature heat pump or biomass boiler. On the other hand, a highly variable load with frequent shutdowns and turndowns is more amenable to an electrode boiler with rapid start capability.

- Energy storage options — Types of energy storage options are characterised by length of operation enabled and ‘round trip’ efficiency. Storage or buffer tanks may provide short-term storage cheaply, while batteries may provide hours or days of back-up, while longer than that may require a stand-by plant.

- Seasonality — Facilities with different seasonal demand variation will find different fuel choices attractive. For example, summer-weighted demand may find that cheaper electricity rates or effective on-site solar generation makes electricity a preferred fuel.

By making the move early, we stand to save more in terms of both operational costs, and emissions.

Understanding the costs involved

Capital cost

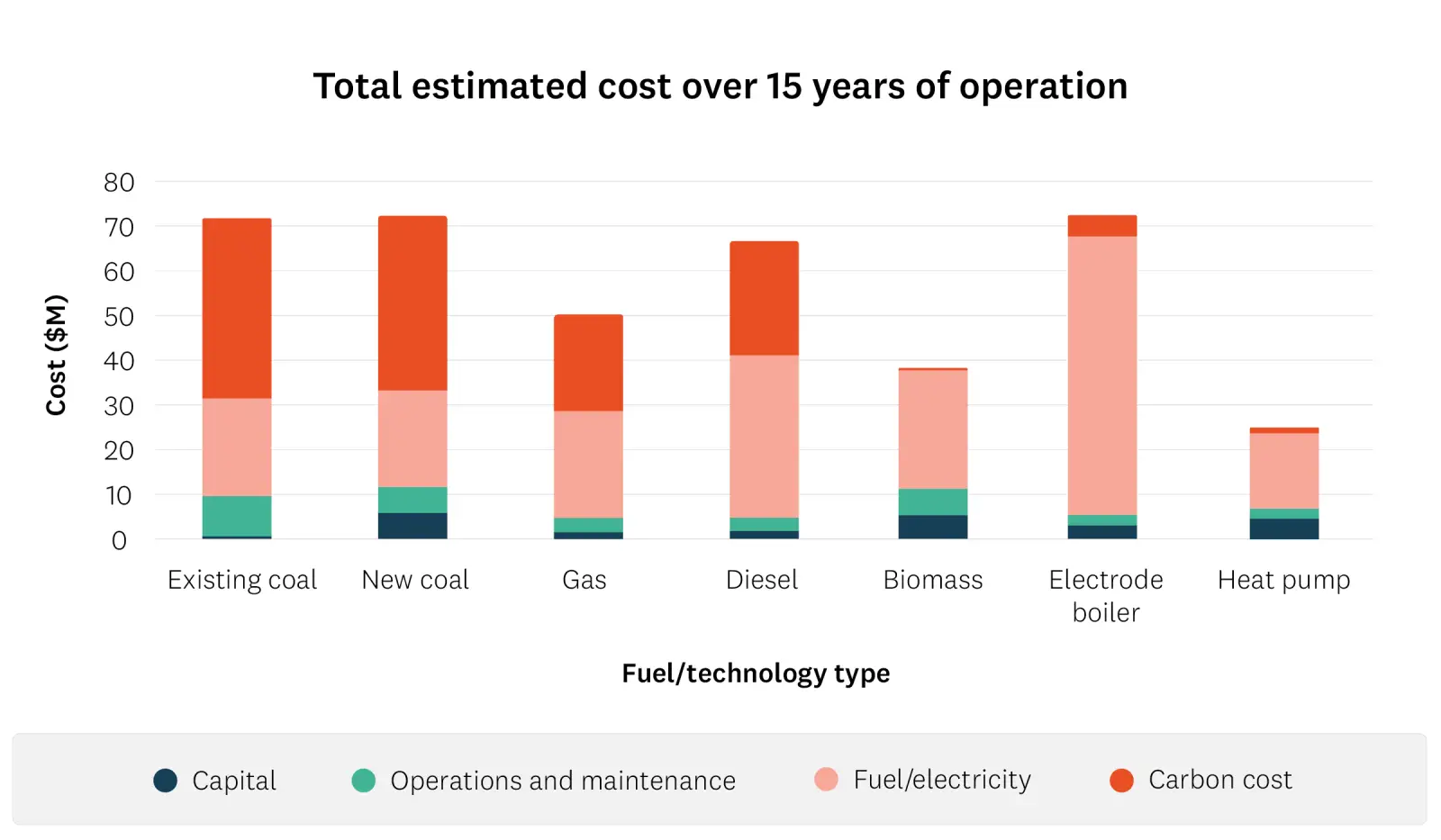

In general, low emission options fall into two categories — high and low capital cost. Choosing between options is hard to generalise, as fuel costs, network capacities and end-use needs vary widely.

- For businesses with high usage needs (e.g. 24/7 operations or >6,000 hours per year) and a long operating horizon, the options with higher capital cost and lower operating costs generally work out more cost effective in the long run such as new biomass boilers and high temperature heat pumps.

- Sites that have low usage needs (<2,000 hours per year) may prefer options with fast start-up and response times such as electric boilers.

- Sites that operate between 2,000 and 6,000 hours per year could go either way depending on the process needs and specific site circumstances.

Higher capital cost options:

- New biomass boilers

- Heat pumps

- Electric boilers

- Biogas production

Lower capital cost options:

- Biogas conversions

- Biomass co-firing

- Retrofitted boilers/heat plants

Operating costs

Operating costs of renewable options are now often less than existing fossil fuel options, particularly for heat pumps and lower cost biomass options such as hog fuel. Once current and future carbon costs are taken into account, low emission options generally lead to reduced operating costs, with the exception of electric boilers due to their high energy costs.

Return on investment

Low emission process heat options will generally have a positive return on investment on a total cost of ownership basis, although payback periods may be longer than many businesses anticipate.

Heat pumps and biomass boilers often have the lowest payback periods for business due to their low operating costs.

Combining fuel switching with demand reduction and energy efficiency can greatly improve the economic and financial outcomes. Implementing demand reduction and energy efficiency means businesses require a lower capacity boiler and therefore lower capital and operating costs.

Read next

-

Industrial heat pumps for process heat

Information for businesses looking for low-carbon alternatives to fossil-fuelled boilers.

- Process heat

-

Biomass boilers for industrial process heat

Information for businesses looking for low-carbon alternatives to fossil-fuelled boilers.

- Process heat

- Decarbonisation

- Fuel switching

-

Case studies: biomass boilers for process heat

Projects at Fonterra, Golden Bay Cement, McCain and JS Ewers offer insight for businesses considering biomass energy.

- Case study

- Process heat

- Fuel switching