Heating water in industrial and commercial businesses uses around 10% of all non-transport energy in New Zealand1, and much of this energy comes from fossil fuels. Businesses can significantly decrease emissions by upgrading to hot water heat pumps.

Hot water heat pumps are a low-emissions alternative to the traditional technology used to produce hot water for consumption and space heating in commercial buildings.

Hot water heat pumps

- Hot water heat pumps may be suitable for commercial buildings that require hot water between the temperatures of 40-90°C for space and water heating.

- If your heating/cooling needs are being met through fossil fuels (for example a gas water califont/instantaneous gas, or fossil fuelled boiler) or electric resistance heaters, then it is time for you to consider upgrading.

- Although initial costs are significant, the ongoing costs associated with hot water heat pumps are normally lower – including energy bills and associated maintenance.

- Most hot water heat pumps will deliver a coefficient of performance (COP) of around 3-4, which means that operating costs are around 25-35% of an electric resistance unit, or around 50% if switching from gas.

- The high efficiency associated with hot water heat pumps can significantly reduce or even eliminate the need for a network connection upgrade if electrifying.

On this page:

- What are hot water heat pumps

- How does a hot water heat pump work?

- What commercial businesses are heat pumps suitable for?

- Benefits of hot water heat pumps

- Case study: George Manning Heritage Lifecare

- Is a hot water heat pump the right option for your business?

- Breaking down the costs

- Challenges to consider

- Other considerations

What are hot water heat pumps?

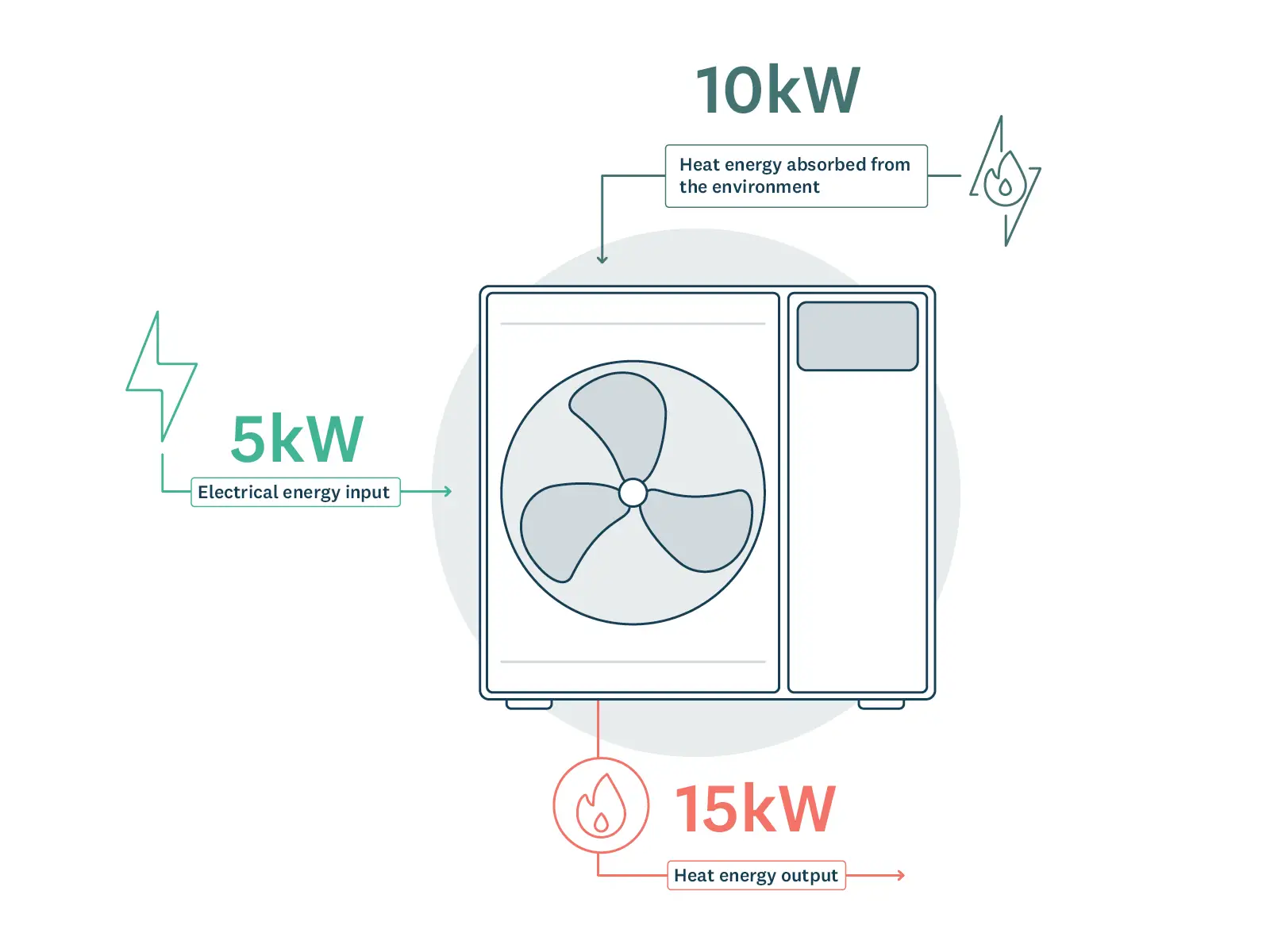

Heat pumps are high-efficiency heat sources that upgrade ambient or waste heat to useful temperatures by using relatively small amounts of electricity. Hot water heat pumps are used for water or space heating.

Despite common misconceptions, a commercial hot water heat pump is generally an off-the-shelf product that can produce temperatures between 40-90 degrees. Units can often be linked together to supply larger energy demands as needed.

They are a low emissions option as they make use of New Zealand’s highly renewable electricity (which is 80-85% renewable). In addition, their high efficiency means that electricity goes further, and the need for network upgrades is reduced.

Heat pumps (including hot water heat pumps) are emerging as key tools to decarbonise commercial and industrial process heat and hot water needs.

How does a hot water heat pump work?

Hot water heat pumps operate on the principle of heat transfer. They use a refrigerant that absorbs heat from the surrounding air, or from a waste heat source. The refrigerant is ideally carbon dioxide as it is the safest and has the lowest Global Warming Potential (GWP), but it could be propane, ammonia, or a synthetic chemical.

The refrigerant is compressed to increase the temperature, and then transfers the heat to water which can be used for commercial heating purposes such as hot water in your building’s bathrooms and kitchens, as well as for space heating such as underfloor and radiator heating.

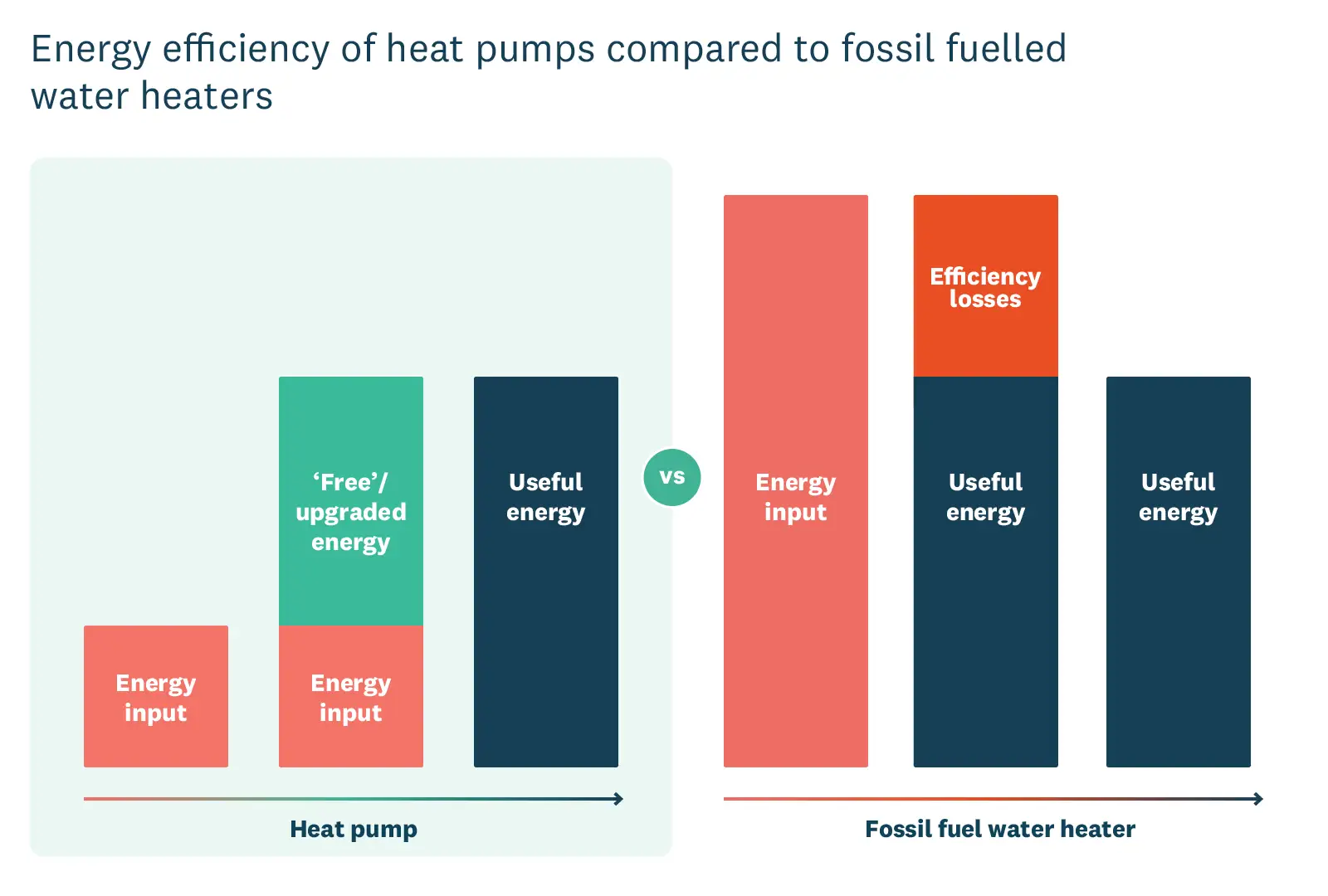

This process supplies heat more efficiently than heating the fluid through conventional means (such as a fossil fuelled boiler) because it is upgrading existing heat to a more useful form, which takes less energy than generating it directly.

What commercial businesses are heat pumps suitable for?

Commercial hot water heat pumps are gaining popularity both internationally and here in New Zealand for process heat and hot water requirements. Types of businesses that are switching include:

- Offices

- Gyms

- Apartment buildings

- Aged residential care facilities

- Restaurants

- Clubs and facility centres

- Hotels

- Swimming centres

Benefits of hot water heat pumps

- Highly efficient – Heat pumps have coefficients of performance (COP) of around 3-4. In comparison, fossil fuel boilers typically have a COP of 0.75 to 0.95. The high COP combined with New Zealand’s low carbon electricity generation enables a very low-carbon and highly efficient way of generating heat with substantially less energy loss than combustion processes.

- Low operating costs – Because of the high COP, operating costs are typically around 25-35% of an electric resistance unit, or around 50% of an equivalent gas unit.

- Convenience – Commercial hot water heat pumps are easily installed, and they avoid boiler house costs. Heat pumps can often use existing electricity supplies when retrofitted.

- No products of combustion – Electrically driven hot water heat pumps have no products of combustion to dispose of such as ash, or flue gases like oxides of nitrogen (NOx) or sulphur (SOx), and no coal dust. They are therefore cleaner to operate than a boiler-based heating system and air quality is better. Because of this, air discharge resource consents are not required.

- Safe and highly durable – Heat pumps are reliable. They contain proven components and built-in controls to self-regulate their operation.

- Smaller physical size in comparison to boilers – Fuel storage is not required which can greatly reduce the physical size of the heating system compared to a fossil fuelled alternative.

- Future proofing – Future power grids will require more rapid responses to changes in demand, and heat pumps can offer cost-effective demand response capabilities.

- Noise levels – Noise levels of a hot water heat pump are typically around 50-60 decibels, which is equivalent to a quiet conversation. The low noise levels mean that hot water heat pumps can be used in a range of settings.

Case study: George Manning Heritage Lifecare

George Manning Heritage Lifecare is an aged care facility in Christchurch. In 2022 they undertook a decarbonisation project that involved replacing the existing diesel space-heating and resistance (electric) heated domestic water heating with variable flow heat pump water heating systems. The project also included installing a 25kWp solar PV system.

The project decreased the site's emissions by 75%. It has resulted in cost savings of approximately $137,500 per year — a four-year payback period on the $527,000 capital cost.

During the 10.5 months from July 2022 to May 2023, which covers commissioning of the Solar PV system and the domestic hot water module and space heating hot water heat pumps, electricity usage was reduced by 72,000 kWh at a value of $14,300, with 32,000 kWh produced by the solar panels.

The diesel boiler was removed in October 2022. In the 6 months following its removal, the site avoided diesel usage of 33,000L compared to the same period a year earlier. This represents savings of $62,000 (calculated at June 2023 diesel prices of approx. $1.80/L).

Key project stats

- Project — Installation of solar PV and hot water heat pump water and space heating systems

- Project location — Christchurch

- Project timeline — June 2022-June 2023

- Hot water heat pump capacity — 4x 90 kW output (space heating) and one 50kW output (domestic hot water)

- Estimated annual emissions saving — approx. 200 tCO2e (a 75% decrease for the site, and a 98% decrease for the heating system)

- Project cost — $492,000 for heat pumps and $35,000 for solar PV

- Estimate annual cost saving — $137,540

- Payback period — 4 years

This case study was supplied by Decarbonised Energy Solutions and Sunshine Solar.

Is a hot water heat pump the right option for your business?

Adopting hot water heat pumps for hot water and space heating requirements in commercial buildings may be a good move for you if some or all of the following apply to your business:

- You are after a way to efficiently generate hot water or space heat that has a lower operating cost than traditional fossil fuel or electrical resistance options.

- You require hot water or space heating between 60-100 degrees.

- You are looking at ways to decarbonise your business.

Breaking down the costs

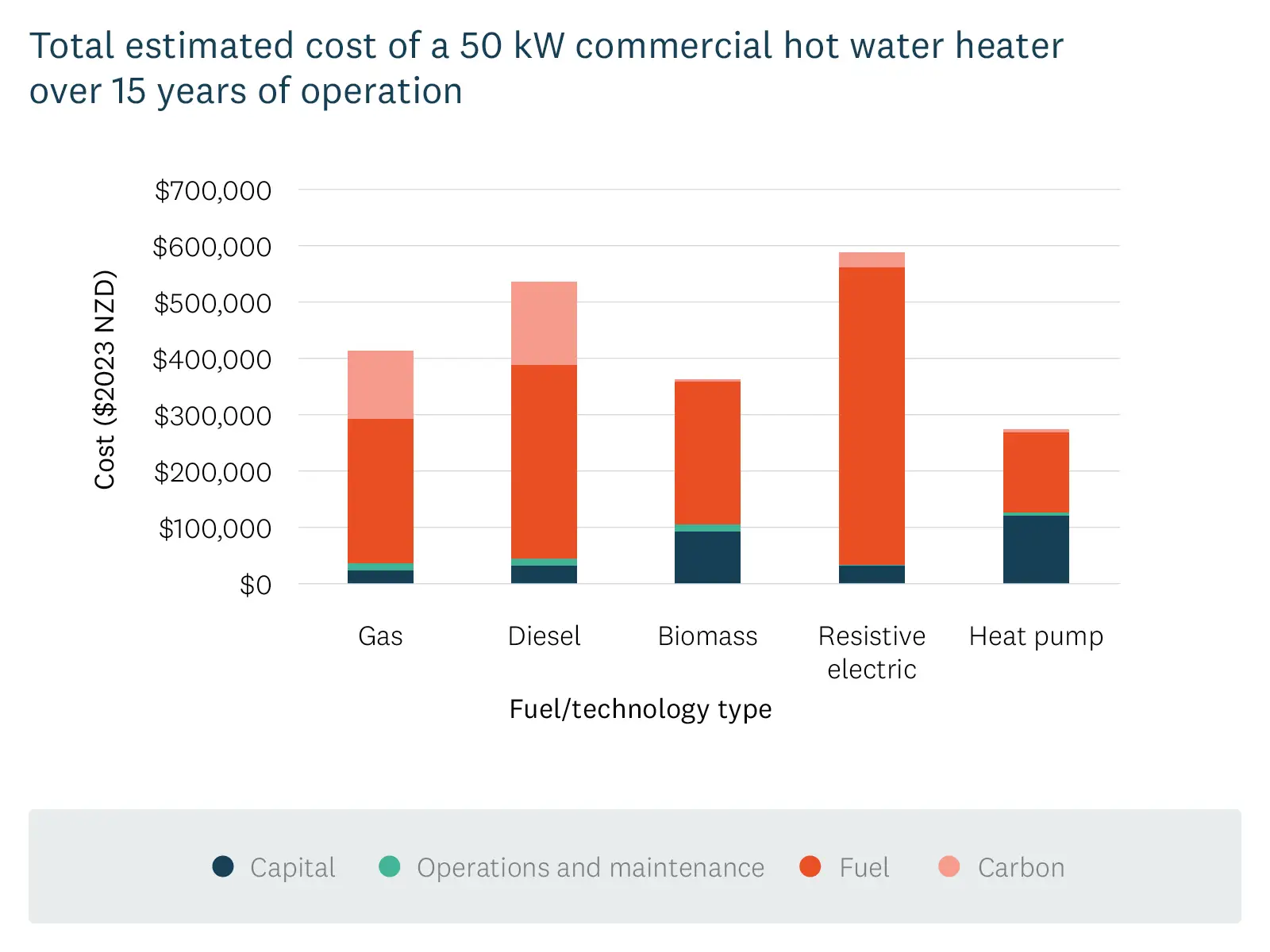

While installing a hot water heat pump will be an upfront cost to your business, there is significant potential to save costs in the medium-long term. There are also other hidden cost savings that businesses should consider when determining whether to make the switch.

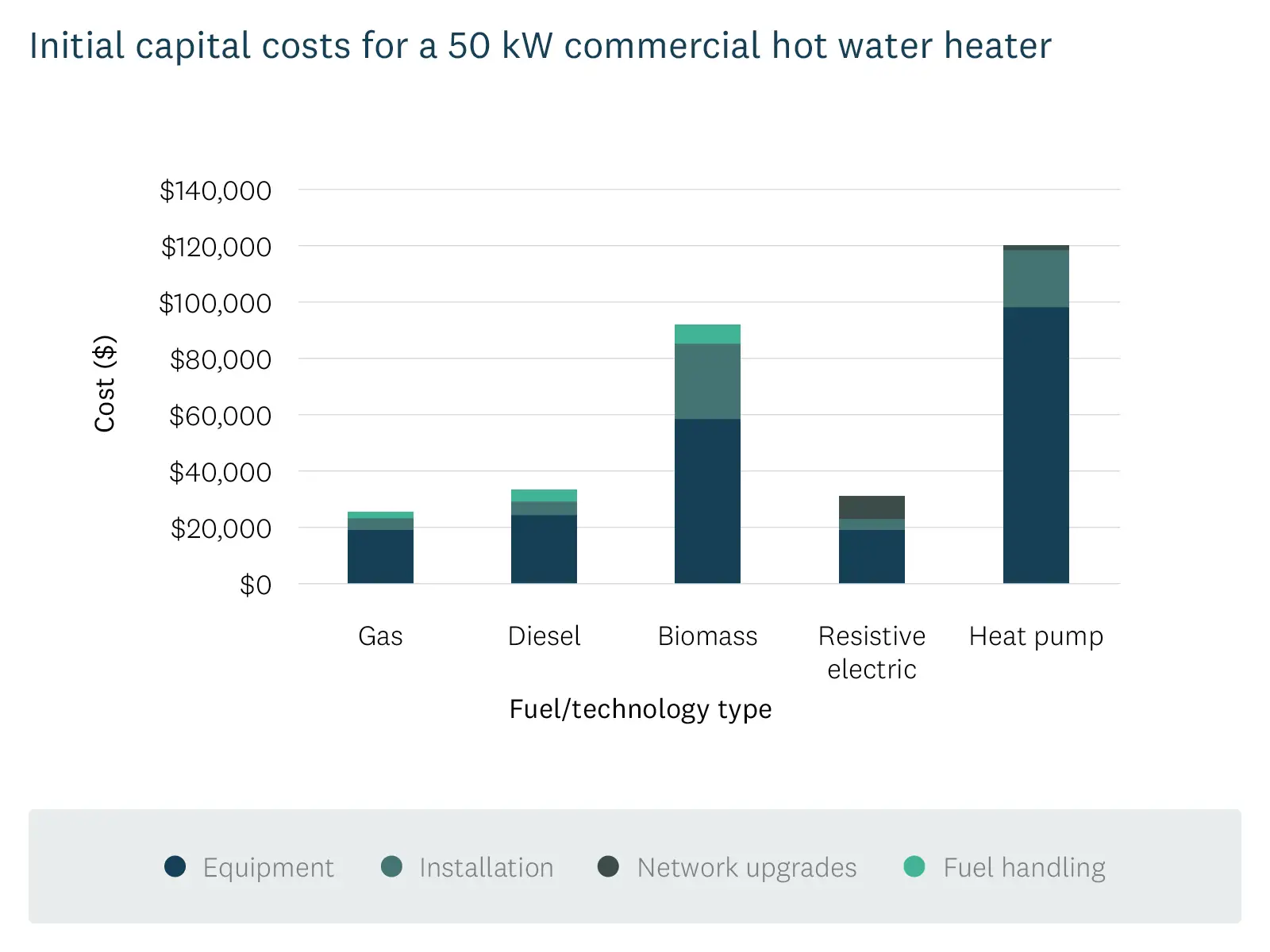

Capital cost

In general, a hot water heat pump is likely to have a capital cost including installation of 3 to 5 times higher than an equivalent gas, liquid fuel, or electric resistance heater. The below graph illustrates the comparative capital costs for 50kW commercial hot water heater units.

Running costs

The capital cost is offset by energy cost savings in the medium to long term. Typically, a heat pump will deliver heat energy between 3 to 4 times the supplied electrical energy. What this means is that heat pumps are highly efficient at transforming electricity into heat.

For example, if electricity is $0.15 per kWh and the heat pump has a coefficient of performance (COP) of 4.0, and natural gas for an 80% efficient gas water heater is $15 per GJ, then the energy costs to run the heat pump will be around 55% of those to run a gas water heater.

Other cost considerations

- A heat pump will use less electricity than an equivalent electric resistance heater.

- Gas connection charges can be significant so if your site is removing gas altogether there could be additional savings.

- The high efficiency associated with heat pumps can significantly reduce or even eliminate the need for a network connection upgrade when compared with installing electric resistance heaters.

- A heat pump will generally reduce carbon emissions from heat delivered by 85 to 95%, depending on efficiency and the fuel replaced. As costs associated with emissions are expected to rise, this can deliver significant cost savings.

- Heat pumps may require less supervision and operator intervention and are safer for staff and building occupants.

The below graph shows the estimated cost of a 50 kW commercial hot water heat pump over 15 years of operation. Heat pumps are the most cost-effective solution over the medium to long term.

Save costs by improving energy efficiency first

Optimising and improving the way your existing equipment performs can save energy and costs in the short term, before you upgrade to new technology. This approach helps to ensure that when you do make the switch to a hot water heat pump, that your energy demand is as efficient as possible.

Sign up to our Commercial Buildings Decarbonisation Pathway for step-by-step decarbonisation support.

Challenges to consider

While there are many advantages to adopting hot water heat pumps for commercial buildings, there are also potential challenges that businesses should consider before making any decisions.

Some challenges with hot water heat pumps include:

- Network charges – Capacity, time of use and peak demand charges may mean that electric water heating, including heat pumps incur significant costs during certain periods. It may make sense to add additional hot water storage for use during peak-electricity demand periods and to increase system resilience. Variable speed control can also allow the electrical demand of the heat pump to be temporarily lowered in times of high site or network electrical demand, to respond to electricity tariff rates or participate in demand-response programmes.

- Electricity supply requirements – Heat pumps typically draw around a quarter to a third of the equivalent thermal energy load as electricity so they may require an increase to a site’s electricity supply capacity. Cabling and switching equipment on-site can be expensive - especially for longer distances.

- Heat source quality – Heat pumps require reliable heat sources for efficient operation. The heat pump needs to draw fresh air past it to extract heat. Heat pumps have reduced performance and output during cold weather and the system needs to be designed accordingly.

- Low utilisation factors – A heat pump is a high capital cost item, so if your utilisation factors are low, for example if the building has infrequent or highly seasonal occupancy, the energy and carbon savings might not be high enough to recover the capital cost in which case lower capital cost options such as electric resistance heaters may be appropriate.

- Maintenance – heat pumps require maintenance to keep them running efficiently. This includes for checking the refrigerant levels, cleaning the air filters, and checking the electrical connections.

Other considerations

The below considerations should also be thought through and planned for to increase chances of a successful switch to a high temperature heat pump.

References

Keep reading

-

Case Study: Hot water, low emissions - Oceania is switching to renewables

Retirement and aged care living provider, Oceania, is upgrading to cleaner technologies in their facilities across New Zealand.

-

Commercial Buildings Decarbonisation Pathway

Our 5-step pathway provides tailored tools and resources to the Commercial Buildings sector to help lower their emissions and unlock business benefits.

-

Commercial Buildings Tools and Resources

Explore our resources for NZ commercial buildings and begin your decarbonisation journey.